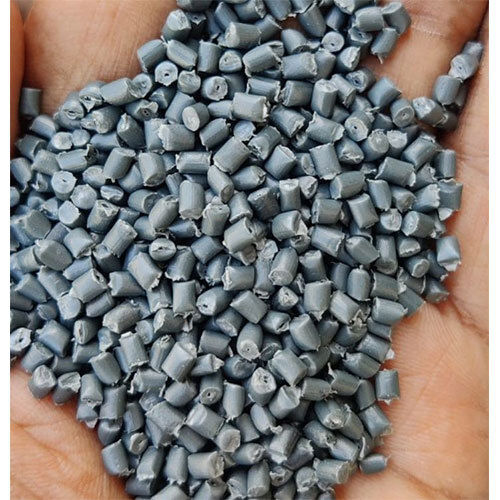

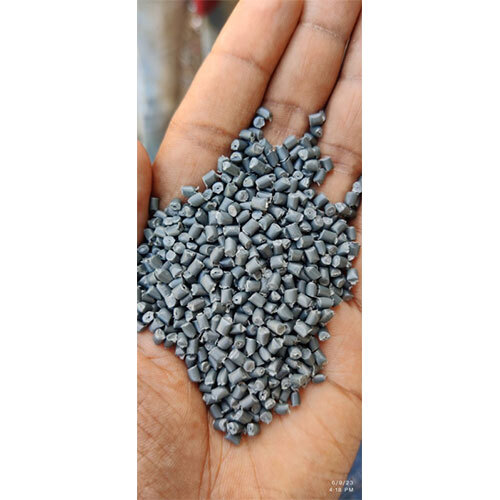

Silver HDPE Granules

Silver HDPE Granules Specification

- Thickness

- Customizable as per requirement

- Usage & Applications

- Injection molding, blow molding, film manufacturing, pipe production, plastic containers, automotive parts

- Packaging Type

- Plastic bag / Sack

- Hardness

- Shore D 65-69

- Form

- Granules

- Material

- High Density Polyethylene (HDPE)

- Type

- Other

- Material Feature

- High Durability

- Density

- 0.97 Gram per cubic centimeter(g/cm3)

- Grade

- HDPE

- Tensile Strength

- 31 MPa (approx.)

- Melting Point

- 120C 135C

- Weight

- 25 kg per bag (typical packaging)

- Color

- Silver

- Contaminants

- Free from visible impurities

- Elongation at Break

- >600%

- Odor

- Odorless

- Processing Temperature

- 180C 240C

- MFI (Melt Flow Index)

- 0.35 1.5 g/10min (as per requirement)

- Appearance

- Uniform Silver Colored Pellets

- Moisture Content

- <0.1%

- Resin Purity

- 99% minimum

- Recyclability

- Yes, fully recyclable

Silver HDPE Granules Trade Information

- Minimum Order Quantity

- 40 Bags

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- 25 KG

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Silver HDPE Granules

Silver HDPE (High-Density Polyethylene) granules are small, pellet-like pieces of a high-density polyethylene material that has been colored or coated in a silver hue. HDPE is a versatile, durable, and lightweight thermoplastic polymer that is commonly used in various industries for producing products like containers, bottles, pipes, and plastic parts.

The silver coloration might be achieved through the addition of metallic pigments or other additives during the granulation process. These granules are used for manufacturing silver-colored plastic items or for adding a metallic finish to the surface of products made from HDPE.

Versatile Applications Across Industries

Silver HDPE Granules are expertly crafted for use in a wide array of production processes. They support injection and blow molding, film manufacturing, and the making of pipes, containers, and automotive parts. Their high durability and strength characteristics make them ideal for manufacturers, suppliers, and distributors seeking reliable material performance in demanding applications.

Superior Quality and Environmental Responsibility

With a resin purity of 99% minimum, these granules are free from visible contaminants, ensuring consistent output quality. Their complete recyclability and low moisture content underscore a commitment to sustainability and environmentally responsible manufacturing. These features help reduce material waste while maintaining product performance and reliability.

Customizable Packaging and Processing Capability

Available in 25 kg bags with customizable thickness, Silver HDPE Granules cater to various industrial requirements. The recommended processing temperature of 180C to 240C promotes efficient manufacturing operations. Their stable melt flow index allows for precise control during molding, which enhances both productivity and the quality of finished goods.

FAQs of Silver HDPE Granules:

Q: How should Silver HDPE Granules be processed for optimal results?

A: The recommended processing temperature for Silver HDPE Granules is between 180C and 240C. Adjusting the temperature within this range helps ensure the material flows correctly, leading to consistent product quality in injection or blow molding, film production, or pipe manufacturing.Q: What are the main benefits of using Silver HDPE Granules in manufacturing?

A: These granules offer high durability, a tensile strength of approximately 31 MPa, and an elongation at break exceeding 600%. With a 99% purity level and recyclability, they deliver both performance and environmental advantages, making them ideal for quality-conscious manufacturers.Q: When is it best to utilize Silver HDPE Granules in production?

A: Silver HDPE Granules are best used when high durability, chemical resistance, and form stability are required. Industries such as packaging, automotive, and construction benefit during the production of robust plastic containers, pipes, and automotive parts.Q: Where can Silver HDPE Granules be purchased or sourced in India?

A: You can obtain Silver HDPE Granules from dealers, distributors, exporters, fabricators, manufacturers, retailers, suppliers, traders, and wholesalers throughout India. Many offer customizable packaging and guidance on suitable applications.Q: What is the process for ensuring the purity and quality of these granules?

A: Silver HDPE Granules are produced with strict quality controls to guarantee a minimum of 99% resin purity and are free from visible contaminants. Each batch undergoes moisture and impurity testing to ensure consistency and reliability for end users.Q: How can Silver HDPE Granules contribute to eco-friendly production?

A: These granules are fully recyclable and designed for efficient reuse, aligning with sustainable manufacturing goals. Their high purity and odorless nature ensure minimal environmental impact and reduce waste in the production cycle.Q: What applications are Silver HDPE Granules best suited for?

A: They are ideal for injection molding, blow molding, film manufacturing, pipe production, automotive components, and containers. Their customizable thickness adds versatility for various specialized manufacturing needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Granule Category

Yellow HDPE Granules

Price 62 INR / Kilograms

Minimum Order Quantity : 40 Bags

Material Feature : High chemical resistance, Nontoxic, UV resistance

Grade : Blowing

Density : 0.97 Gram per cubic centimeter(g/cm3)

Color : Yellow

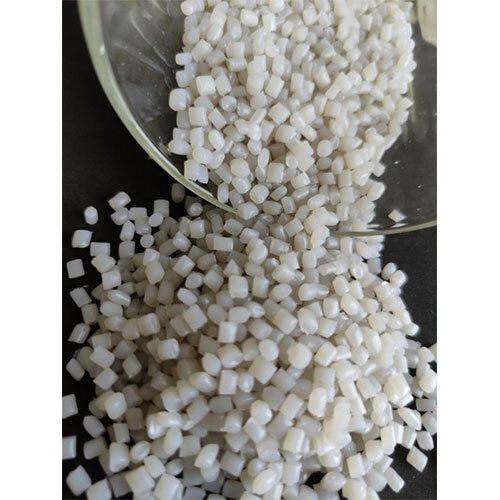

Natural White HDPE Granules

Price 82 INR / Ton

Minimum Order Quantity : 40 Bags

Material Feature : High durability and chemical resistance

Grade : Industrial

Density : 0.93 Gram per cubic centimeter(g/cm3)

Color : Natural White

HDPE Pipe Granules

Price 74 INR / Bag

Minimum Order Quantity : 40 Bags

Material Feature : Plastic

Grade : Industrial

Density : 0.91 Gram per cubic centimeter(g/cm3)

Color : Black

Super Milky White HDPE Granules

Price 61 INR / Bag

Minimum Order Quantity : 40 Bags

Material Feature : High Density Polyethylene (HDPE)

Grade : Super

Density : 0.970 Gram per cubic centimeter(g/cm3)

Color : Milky White