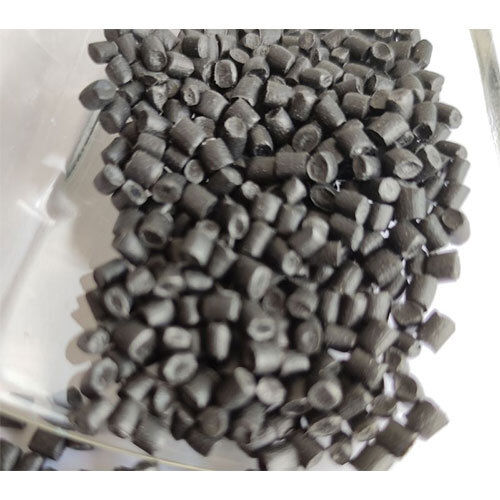

Virgin LDPE Granules

Virgin LDPE Granules Specification

- Type

- Other

- Material Feature

- Low Density Polyethylene (LDPE)

- Density

- 0.93 Gram per cubic centimeter(g/cm3)

- Grade

- Virgin

- Tensile Strength

- 1030 MPa Kilopascals (KPa)

- Melting Point

- 105115C

- Weight

- Customizable Kilograms (kg)

- Color

- White

Virgin LDPE Granules Trade Information

- Minimum Order Quantity

- 40 Bags

- Packaging Details

- 25 kg

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Virgin LDPE Granules

Virgin LDPE (Low-Density Polyethylene) granules are the raw form of LDPE plastic, which is used to produce a wide range of products. LDPE is a thermoplastic polymer made from the polymerization of ethylene monomers. It has a low-density structure, giving it flexibility, low hardness, and high chemical resistance.

Here are some characteristics and common applications of Virgin LDPE Granules:

Characteristics:

- High Flexibility: LDPE has excellent flexibility and can be easily molded and processed into various shapes and forms.

- Low Melting Point: It has a relatively low melting point, typically around 105115C (221239F), which makes it easy to process.

- Translucent Appearance: Virgin LDPE has a translucent, slightly opaque appearance.

- Chemical Resistance: LDPE is resistant to acids, bases, and many solvents, making it durable in harsh environments.

- Lightweight: LDPE is a lightweight material that is commonly used in packaging.

- Non-toxic: LDPE is non-toxic, which makes it suitable for use in food packaging and medical applications.

Common Applications:

- Packaging Films: LDPE is widely used for producing plastic bags, shrink films, and liners due to its flexibility and durability.

- Containers and Bottles: It is used in the production of bottles, containers, and other packaging items.

- Toys and Household Items: LDPE is used to make toys, furniture, and household goods.

- Wire and Cable Insulation: It is used as insulation for electrical cables due to its electrical insulating properties.

Virgin vs. Recycled LDPE:

- Virgin LDPE: This is the raw, unprocessed material that has not been recycled. It offers better quality, fewer impurities, and is generally more suitable for food and medical-grade products.

- Recycled LDPE: Recycled LDPE is made from post-consumer or post-industrial LDPE waste and may have some degradation, but it is more environmentally friendly and cost-effective.

FAQs of Virgin LDPE Granules:

Q: What is the grade of the LDPE granules?

A: The LDPE granules are of virgin grade.Q: What is the color of the LDPE granules?

A: The LDPE granules are white in color.Q: What is the melting point range of the LDPE granules?

A: The LDPE granules have a melting point range of 105115C.Q: What is the material feature of the LDPE granules?

A: The LDPE granules are made of Low Density Polyethylene (LDPE) material.Q: What is the density of the LDPE granules?

A: The density of the LDPE granules is 0.93 Gram per cubic centimeter (g/cm3).Q: What is the tensile strength range of the LDPE granules?

A: The LDPE granules have a tensile strength range of 1030 MPa.Q: Is the weight of the LDPE granules customizable?

A: Yes, the weight of the LDPE granules is customizable.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in LDPE Granule Category

Tarpaulin LDPE Granules

Price 100 INR / Kilograms

Minimum Order Quantity : 40 Bags

Grade : Industrial

Material Feature : Lightweight Durable

Color : Black

Type : LDPE

White LDPE Granules

Minimum Order Quantity : 40 Bags

Grade : Industrial

Material Feature : High Quality

Color : White

Type : LDPE

Natural White LDPE Granules

Price 88 INR / Ton

Minimum Order Quantity : 42 Bags

Grade : Blowing

Material Feature : Recyclable

Color : white

Type : LDPE

Angoori Black LDPE Granules

Price 78 INR / Ton

Minimum Order Quantity : 40 Bags

Grade : Industrial

Material Feature : Recyclable

Color : Black

Type : LDPE