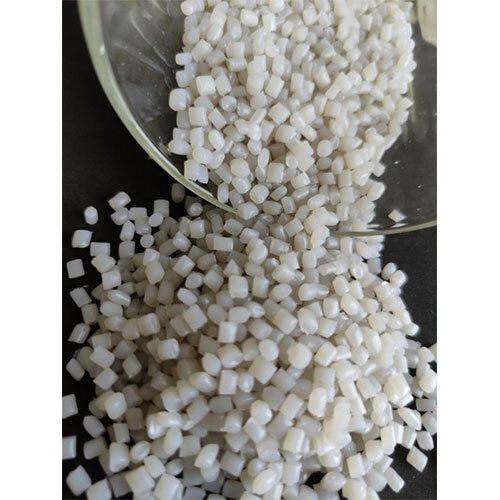

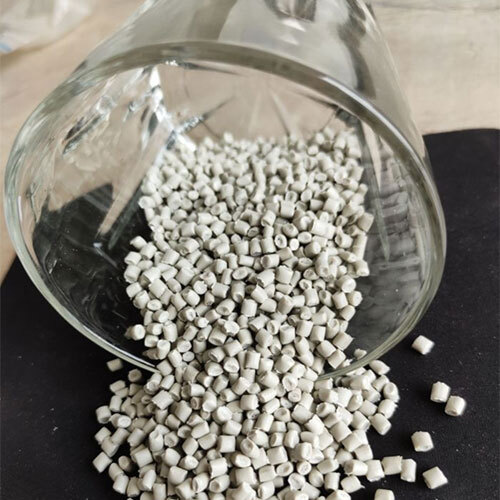

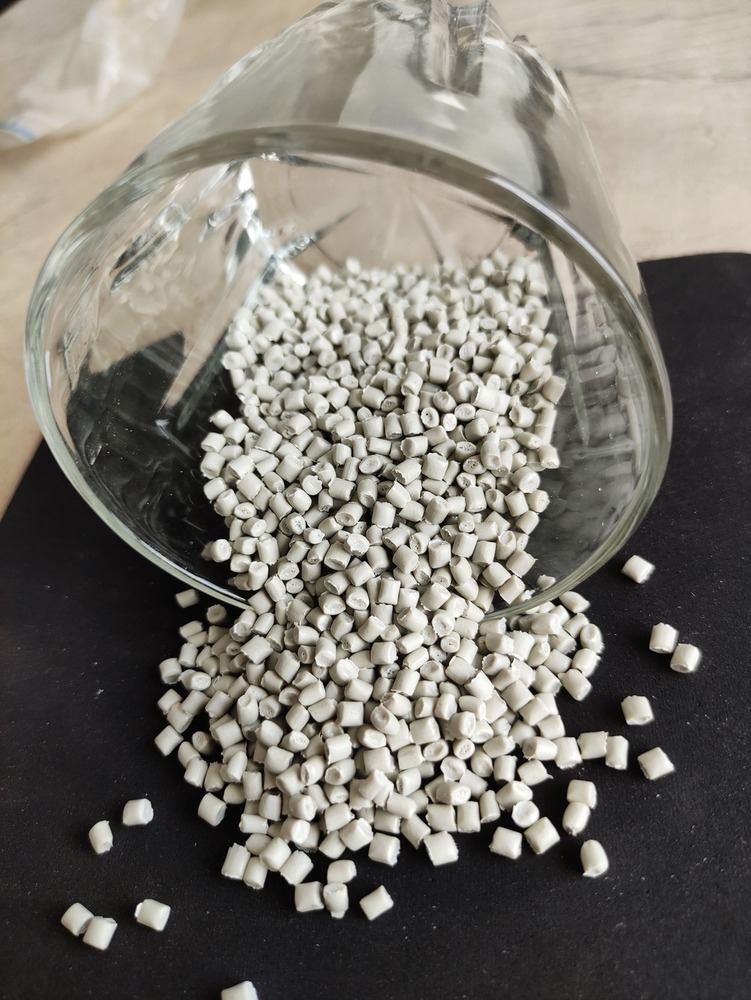

Milky White HDPE Granules

Milky White HDPE Granules Specification

- Thickness

- Customizable based on requirement

- Hardness

- Shore D 6070

- Material

- High-Density Polyethylene (HDPE)

- Packaging Type

- Polypropylene bags

- Form

- Granules

- Usage & Applications

- Plastic molding, manufacturing bottles, containers, pipes, and film products

- Type

- HDPE

- Material Feature

- High impact resistance, chemical resistance

- Density

- 0.97 Gram per cubic centimeter(g/cm3)

- Grade

- Blowing

- Tensile Strength

- 20-40 MPa

- Melting Point

- 125-135C

- Weight

- As per packaging, typically 25kg/bag

- Color

- white

- Appearance

- Milky white, uniform granule

- Surface Finish

- Smooth

- Odor

- Odorless

- Chemical Stability

- Excellent

- Moisture Content

- <0.03%

- Heat Resistance

- Good

- Storage Conditions

- Keep in a cool, dry place

- Processing Method

- Extrusion, Injection Molding, Blow Molding

- Recyclability

- 100% recyclable

Milky White HDPE Granules Trade Information

- Minimum Order Quantity

- 40 Bags

- Packaging Details

- 25 KG

- Main Domestic Market

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

About Milky White HDPE Granules

Milky white HDPE (High-Density Polyethylene) granules are commonly used in manufacturing a wide range of products due to their durability, flexibility, and resistance to chemicals and environmental factors. These granules are typically opaque or white in color, giving them the "milky" appearance. They are made from the polymerization of ethylene and are a versatile material used in various industries, including packaging, construction, and automotive.

Key features of Milky White HDPE Granules:

- Color: Milky or opaque white

- Density: High-density, making it stiffer and stronger than low-density polyethylene (LDPE)

- Durability: Resistant to impact, chemicals, and environmental stress

- Applications: Commonly used for products like bottles, containers, pipes, toys, and other plastic goods

- Processing: Can be processed using injection molding, blow molding, and extrusion

These granules are used as raw material for various manufacturing processes, including blow molding, extrusion, and injection molding, to create products with the desired characteristics like strength, rigidity, and resistance to chemicals and heat.

Versatile Polymer for Industrial Applications

Designed for multiple processing methodsextrusion, injection molding, and blow moldingMilky White HDPE Granules facilitate reliable manufacturing of varied plastic products. Their outstanding chemical resistance and mechanical strength guarantee durability in goods such as bottles, containers, pipes, and films, making them a preferred choice for manufacturers seeking efficiency and versatility in their operations.

Sustainability and Material Excellence

With 100% recyclability and minimal moisture content (<0.03%), these HDPE granules support environmentally conscious production. The granules excellent surface finish and consistent physical properties enhance product quality, while their non-toxic, odorless nature ensures safe usage across a range of industries.

FAQs of Milky White HDPE Granules:

Q: How should Milky White HDPE Granules be stored for optimal quality?

A: To preserve their properties, these granules should be stored in a cool, dry place, away from direct sunlight or moisture. The packaging in polypropylene bags helps maintain low moisture content and ensures granule integrity until processing.Q: What are the main industrial uses of Milky White HDPE Granules?

A: These granules are primarily used for plastic molding processes like extrusion, injection molding, and blow molding to manufacture bottles, containers, pipes, and film products due to their high impact resistance and chemical stability.Q: Where can Milky White HDPE Granules be sourced in India?

A: They are available across India through an extensive network of dealers, distributors, exporters, fabricators, manufacturers, retailers, suppliers, traders, and wholesalers specializing in polymer materials.Q: What processing methods are compatible with these HDPE granules?

A: Milky White HDPE Granules are suitable for extrusion, injection molding, and blow molding methods, making them adaptable for various applications and production environments.Q: What benefits do these granules offer over other grades of HDPE?

A: They deliver outstanding chemical resistance, high impact strength, uniform color and granule size, smooth surface finishes, and full recyclability, making them advantageous for sustainable and long-lasting product manufacturing.Q: When is it recommended to use this grade of HDPE granules?

A: This grade is ideal when manufacturing products that demand high mechanical strength, chemical resistance, and uniform appearance, such as bottles, containers, and pipes, especially when sustainability and recyclability are important factors.Q: What are the recommended processing temperatures for these granules?

A: The granules typically melt between 125-135C, so processing should occur within or slightly above this temperature range for efficient molding and optimal product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in HDPE Granule Category

Silver HDPE Granules

Price 70 INR / Kilograms

Minimum Order Quantity : 40 Bags

Color : Silver

Grade : HDPE

Type : Other

Density : 0.97 Gram per cubic centimeter(g/cm3)

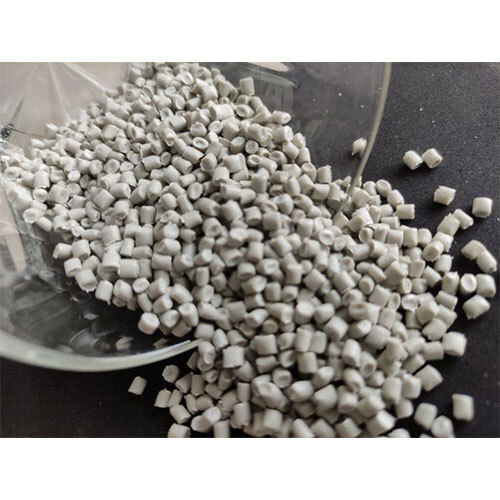

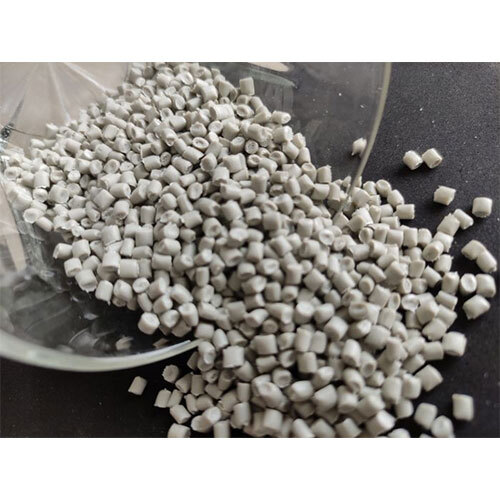

Natural White HDPE Granules

Price 82 INR / Ton

Minimum Order Quantity : 40 Bags

Color : Natural White

Grade : Industrial

Type : Other, HDPE Granules

Density : 0.93 Gram per cubic centimeter(g/cm3)

Fiber Optic Cable Granules

Price 195.00 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Color : Black

Grade : Industrial Grade

Type : Other, Granules

Density : 1.25 Gram per cubic centimeter(g/cm3)

HDPE Pipe Granules

Price 74 INR / Bag

Minimum Order Quantity : 40 Bags

Color : Black

Grade : Industrial

Type : HDPE

Density : 0.91 Gram per cubic centimeter(g/cm3)